The encoder is used to identify the length of the elastic band to ensure that the length ofeach elastic band is consistent.

Ultrasonic welding is adopted, the welding is neat and fimm,and the joints are joined after welding, flat and no opening, and the quality and comfort are improved.

Automatic detection of elastic splicing head, automatic cutting, cutting lengthcan be set.

Standard bottom thread detection device, when the bottom thread is used upand needs to be replaced, it will automatically stop and give an alarm.

Visual recognition system: Aimed at sewing with two-color elastic bands. (Multi-color orsimilar two-color elastic stitching can be equipped with a visual recognition system), whichcan accurately identify the position of the LOGO, and ensure the accurate half folding of theLOGO and the elastic stitching. Each time it can sew one size to two sizes continuously. Thelength of the elastic band can save unnecessary waste of the elastic band.

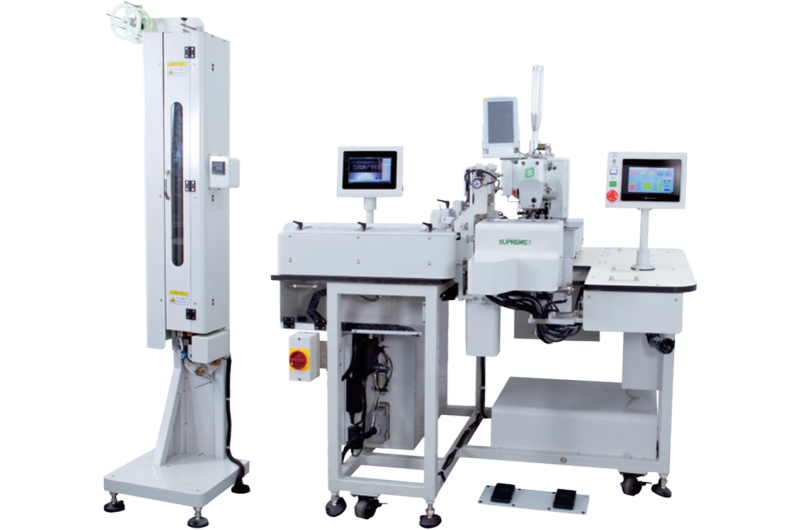

The whole process is automatic operation, automatic feeding, automatic cutting, automaticwelding, automatic sewing, automatic receiving, etc. The number of rubber bandsprocessed per hour is about 650, the output is increased by 5 times, and one person canoperate five machines at the same time.

It is suitable for a variety of specifications of rubber band welding splicing process, smooth and no splicing interface, and the stitches are smooth and beautiful.

Disclaimer: The contents of this catalog are for reference only. Due to ongoing product innovation, the images and specifications shown are subject to change without notice. All product information is subject to the actual product and the latest official specifications.

Official

Official

TikTok

TikTok

Channel

Channel